With all of the work we’ve been doing on the organ and my work schedule, I haven’t been able to post an update on our progress for a few weeks, but here it is!

Lots of activity and progress, with the inevitable hiccups along the way. The pile in the choir room is shrinking, and the organ space is filling up. In fact, it’s really starting to look like an organ in there.

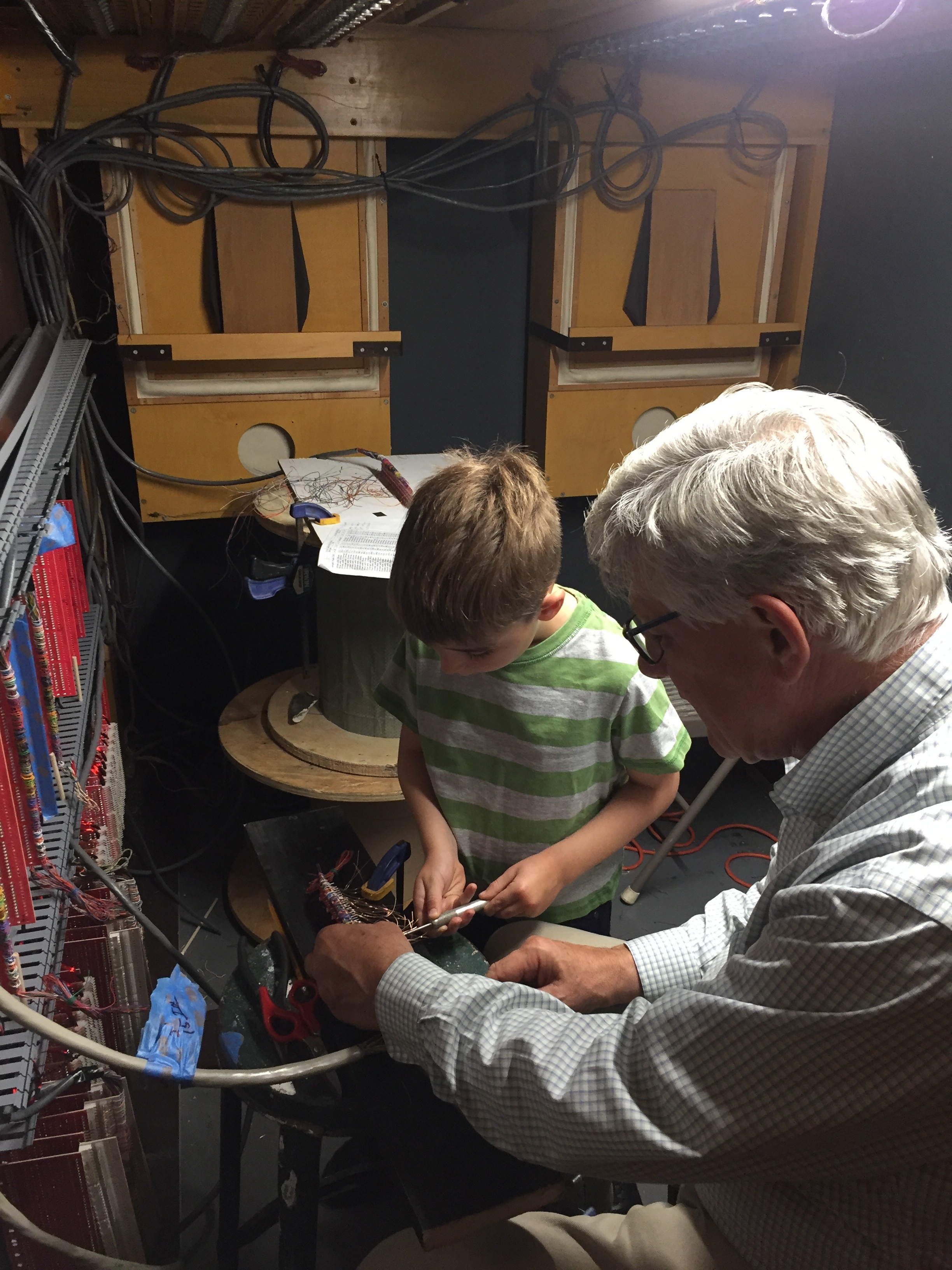

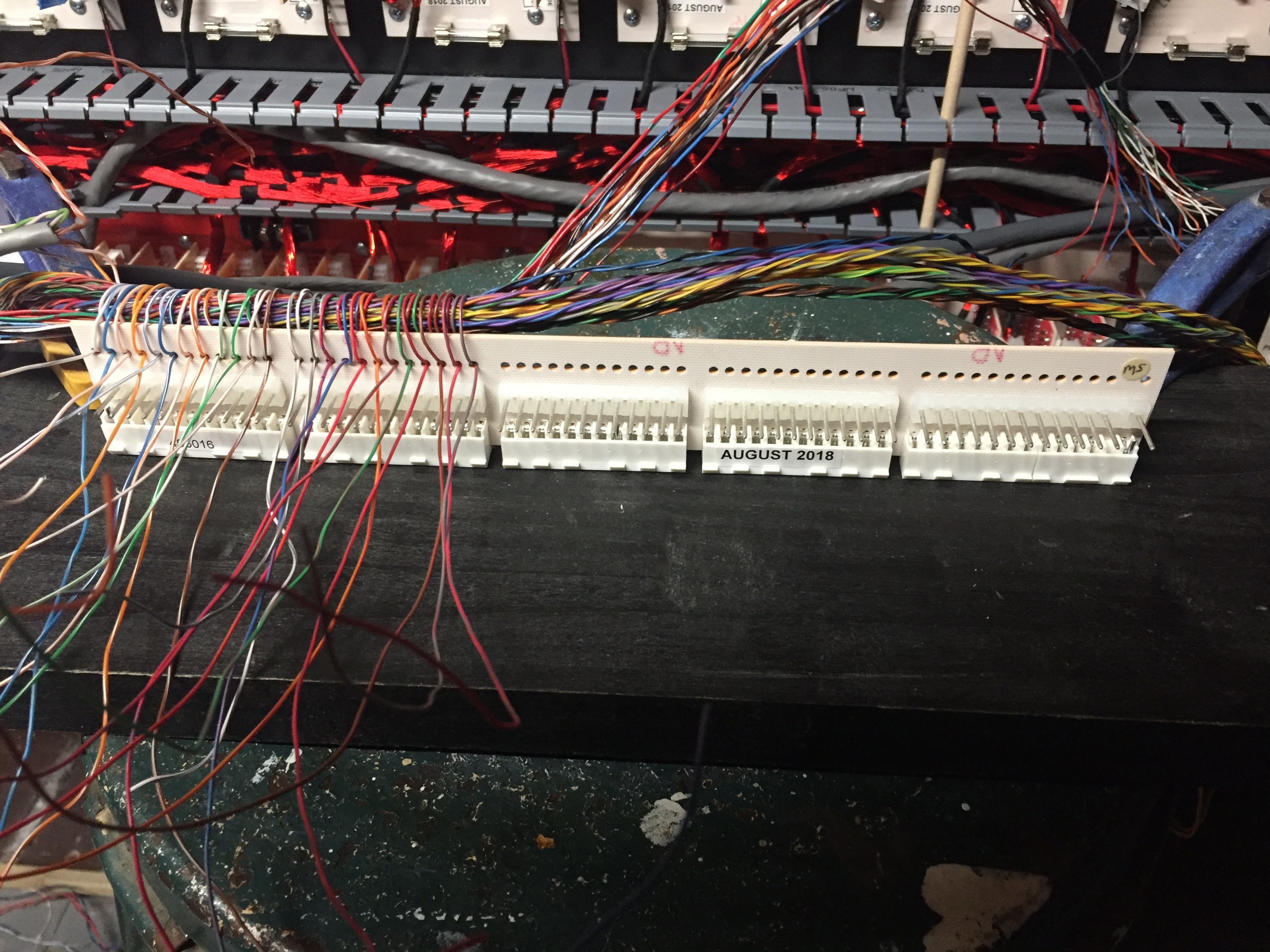

One of the big tasks that’s been taking up our time is wiring the relay. Do you remember all of the foot boards we spent all that time connecting? Well, now we’re connecting the other end of those cables to the relay. Looking at the work, it can be really intimidating; there are hundreds of wires of all different colors that have to go to the right place. However, lots of our volunteers have taken on the challenge, and now we have a half-dozen or so wiring experts among us! Even the Precht and Edwards kids have been jumping in.

Besides wiring the relay, we’ve installed lots of pipes. We have most of the ranks installed on the four main wind chests (2 chests in the swell and great divisions, respectively). As of today, I believe the total is about 11 or 12 ranks out of 17 on those 4 chests. We have a number of smaller offset chests that will take pipes as well, many of them for the pedal division. As a rough estimate, around 700 of the 1500 or so pipes have been installed.

Our new blower also arrived. Since this organ is larger than our old one, it will require more wind, which is supplied by the blower. The new one is from Germany, and is actually quite a bit smaller in size than the old one. It is much more efficient, though, as well as quieter – a testament to the German engineering. That will be installed in the next week or so.

Inevitably, we’ve had our share of small setbacks, too. Nothing major, but one of them was Bill’s discovery that the wind chest at the back of the great division wouldn’t work the way it was installed. It needed to be shifted to the front of the chamber. The second chest would need to be tuned around 180 degrees and shifted to the back of the chamber. These were already assembled, installed, and had some pipes in them, and they’re REALLY heavy. However, Bill attacked it, and is short order the disassembly, shuffling, and re-assembly was done, and all was on track again.

We’ve also discovered some wiring that wasn’t long enough to reach the relay, so we’ve devised work-arounds and fixes for that. We also discovered a problem where the swell shutters were hitting a support structure, as things are a tight fit in there. I devised a quick fix that kept the problem shutter from opening fully, but Tony came up with a better idea to move the offending structure completely out of the way, so we’ll be doing that in the next couple of days.

Finally, we’ve also been fabricating parts as necessary as we go along. The chamber this organ came out of was very different than our organ chamber, so we need to devise different ways of supporting various parts. An example: apparently in the old chamber, the swell wind chests had their opposite end against the wall. A rack supporting the longer Shalmei pipes (called a sky rack) was bolted to this wall. Well, we still need to support the pipes without that wall; time to do some woodworking. We fabricated a support to extend from the wind chest up to the sky rack. In addition, the support for the other end of this rack didn’t make it in the move, so we made one of those, too.

Here’s a list of some of the accomplishments over the last few weeks:

- Installed many of the pipes in the main wind chests (7 out of 9 great ranks and 4 out 8 of swell ranks).

- Installed 3 of the 4 regulator reservoirs on the great and swell wind chests (what a wrestling match that was!).

- Fabricated parts for Schalmei and Chimney Flute sky racks.

- Installed bass Chimney Flute sky rack, wind chest and pipes.

- Wiring of the wind chests to the relay (about 11 of the 18 main ranks are done).

- Secured the swell wind chests to their rear frame with dowels.

- Started reaming and felting rack board holes to fit the Nachthorn rank we’re re-using.

- Bill got under the church and re-routed cables from the console to a new entry point in the organ chamber.

- Removed the old blower.

As we have all along, we’ve had a fantastic turnout of volunteers helping out with this project. Many, many thanks to all of you!:

- Tony Nickel

- Carol & Murray Walker

- David Folsom-Jones

- Caryn Machado

- Allison Gong

- Krys Call

- Liz Wesolowski

- Michael Freeman

- Susan Cavalieri

- Madeline, Oliver, and Alice Precht

- Mike and Corvin Edwards

- Kelly Sutherlin

- Rogan Lynch

And finally, here’s an interesting article about volunteers at Charleston Southern University resurrecting a neglected Moeller organ under the direction of an inspired faculty member:

Resurrecting the music: CSU organ undergoing restoration after decades of sitting silent

A few photos and a video from our work these last few weeks:

Great division pipes

The relay

Oops -Re-arranging the wind chests in the great division.

Oops – footboards off.

Pipes installed in the great division

Alex and Susan working on the relay

New sky rack support for the Schalmei rank

The stack is getting smaller!

Susan wiring on the relay

Relay wiring

Close-up of relay wiring

Allison and Tony install the Spire Flute

Allison picks pipes for the Chimney Flute rank

Bass Chimney Flutes

Some pipes of the great division

Swell pipes

Tony in his wiring office

Bill inspects the new blower

Corvin helps wiring the relay