The last two weeks have seen our organ installation really take it’s final shape. Bill has been working continuously and making rapid progress toward our goal of hearing it in a week for our special Choral Eucharist on Christ the King Sunday.

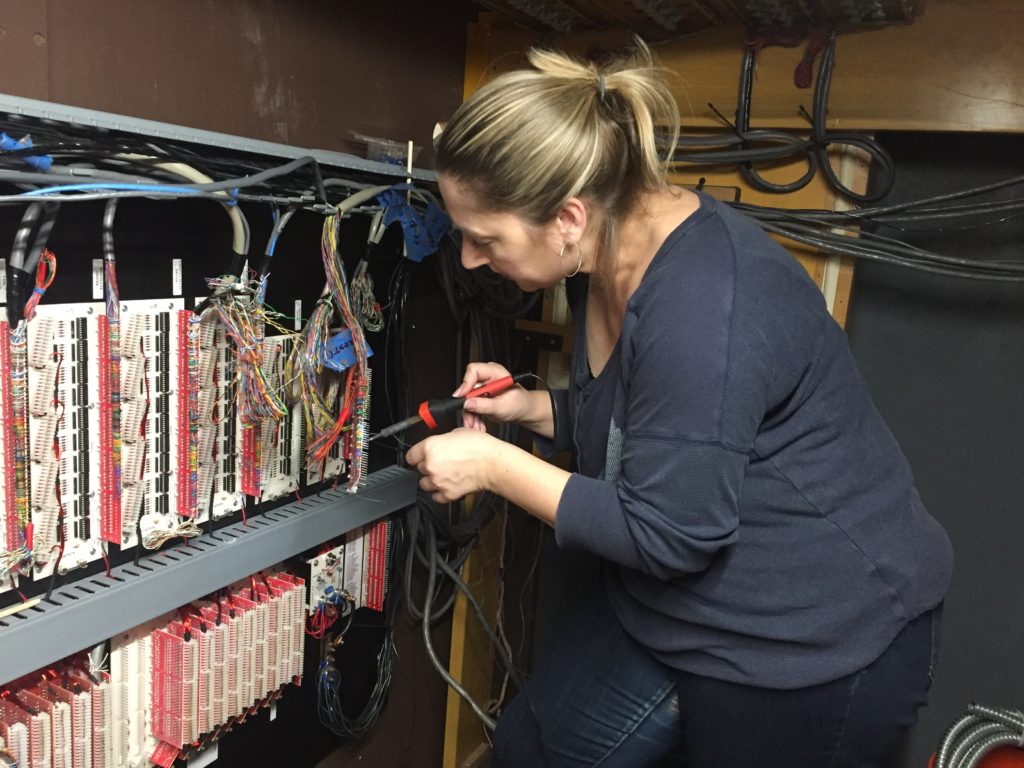

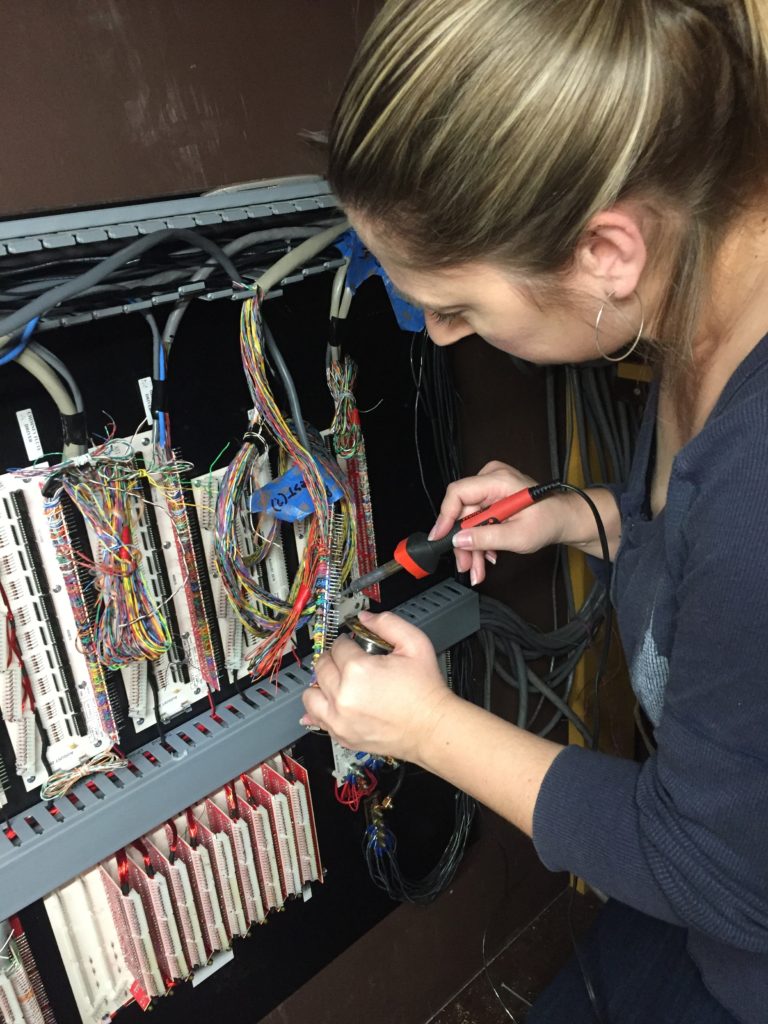

The huge wiring job is finally winding down. Today we wired up our last wind chest (the display chest) to the relay. We have also completed connecting up about half of the return wires – that job should be complete in the next few days, and then we’re done with wiring (except for fixing the inevitable mistakes).

Another wiring task that Tony and I took on was re-installing the rectifier. The rectifier takes the 110v alternating current from the building power, and converts it into direct current power that the organ uses. We already had a perfectly serviceable rectifier with the old organ, so it’s getting reused. It’s been mounted on the wall in the swell, and awaits connection to the relay and console. Tony and I also installed a new light just inside the organ chamber entrance. That corner was becoming rather dark as we installed more and more pipes, so we added a light there for better illumination.

We’ve been installing pipes in the offset wind chests scattered around the organ chamber. Almost all of the large pipes have been squeezed into the swell chamber, and we’re working on fitting pipes into the great chamber. The final ones to go in are the largest pipes for the Sub-Bass pedal rank. That rank is made up of 49 pipes, and they are the only ones in the organ completely fashioned of wood. The smallest is about a foot tall and 2″ in cross-section, while the largest of these are about 8 feet long and around 12″ in cross-section. It’s going to quite a feat to get the 12 biggest of those pipes squeezed into their space just behind the choir partition.

This week the organ was winded, meaning Bill installed all the duct work that carries pressurized air to the various reservoirs, regulators, and wind chests. It was all connected up to the blower, and we turned it on for the first time. I’ve attached a recording of the event in the gallery below, and the sound is…. interesting. Actually, the sound in the recording isn’t really unexpected. In an ideal world, when we first put wind to the organ it shouldn’t make any sound at all, since no stops are pulled and no keys are being held. In fact, we don’t even have power to the key action yet, so nothing would happen if you did press a key.

We don’t live in a perfect world, however – the sound (noise) in the recording are ciphers. They’re notes that are sounding when they shouldn’t be. It’s not entirely unexpected because things like dust and bits of detritus can hold the air valves open and prevent them from closing completely; and there’s been a LOT of dust and detritus generated in this project. We are now going through and locating the pipes with ciphers, then clearing the dust from their valves. Generally it’s not too problematic, as you can use the wind from the organ itself to blow out the dust. But for some of them, we’ve needed to pull down a foot board and clear out the dust from inside the wind chests.

Turning on the blower also reveals all of the air leaks, so we’re going around fixing those as well. As an example, one of the big air leaks was where we forgot to put in a row of about a dozen screws on one side of a swell footboard – oops. We put those in, and that leak was solved. We’ve also found some screws that were stripped out so weren’t sealing well, and those are getting fixed.

The biggest and most obvious of the recent changes is of course our new display pipes mounted in their custom-built wind chest. We installed the wind chest and the pipe support racks last week. This week the pipes went in, and they’re pretty impressive. The wind chest overhangs the partition behind the last choir pew by about 12″. The pipes sit atop the wind chest and extend the full height of the organ chamber, and a little beyond. The pipes have been painted with a gold and silver finish.

Bill gave us some interesting details about the display chest while we were installing it. The visible parts are constructed of yellow pine, and it’s stained to match the woodwork and trim in the sanctuary. Of course our wood work is redwood, so to match it’s reddish color, Hupalo and Repasky used iron filings and vinegar to give the stain a reddish tinge.

Accomplishments over the last couple of weeks include:

- Connected the blower and it’s distribution box

- Winded the organ

- Completed connecting all the signal wiring from the wind chests to the relay

- Continued work connecting the return wires to the relay

- Installed pipes in all the offset chests in the swell chamber (Shalmei, Bourdon, and Viol)

- Installed the first 12 Sub-bass pipes

- Installed the lowest 12 Trumpet and 12 Principal pipes for the Great division in their offset chest

- Installed the last wind regulator

- Pipe fabrication work for bass flue pipes

- Installed the display chest & its pipe support racks

- Installed the display pipes

- Installed a new light in the great chamber

Of courses, all of this progress is possible because of our volunteers, so a huge thanks to:

- Tony Nickel

- Susan Cavalieri

- Murray Walker

- Kymm Walker

- Caryn Machado

- Allison Gong

Rectifier re-installed.

The last regulator.

Bill fixing ciphers.

Winding the Great Division.

Winding in the Swell Division.

Winding of the Great division.

The display chest before installation.

Bill working on the display chest.

Bill installing the stiles on the display chest.

Installing the treble pipes in the display chest.

Display pipes.

Display pipes in their wind chest.

Pipes on the offset chests of the swell division.

Treble pipes for the Sub Bass rank.

8-foot Principals in their offset chest.

Caryn passing resonators in to Murray.

Murray installs the 8-foor Trumpet resonators.

8-Foot Trumpets in their offset chest.

Test fitting the 8′ Sub Bass.

Pipe shop in the Choir Room.

John Rupalo fabricating pipes.

Tony doing some metal fabrication.

Caryn installing return wires.

Alex and Kymm wiring, Tony supervises.

Kymm learning wiring from Tony.

Kymm solders the last rank.